Vibration

Products

We believe in using low noise sensors that have at least a 10kHz flat frequency response and in using 24-bit data converters where technically feasible. Our obsession with quality underpins our measurement systems’ ability to detect faults early to enable that all-important early maintenance intervention.

uClip

Functional Specification – Single channel 24bit measurement Pod

A wearable device that enables the collection of 24bit AC or ICP dynamic data as part of a walkaround vibration measurement system. Designed to deliver optimal quality vibration condition assessment results for an increasingly competitive PdM market. Can be engineered as a White Label product (on request).

Key Features

Uses industry-standard wireless technology (50-75kB/s Transfer rate OTA)

Gathers data from any hard-wired sensors or AC panel

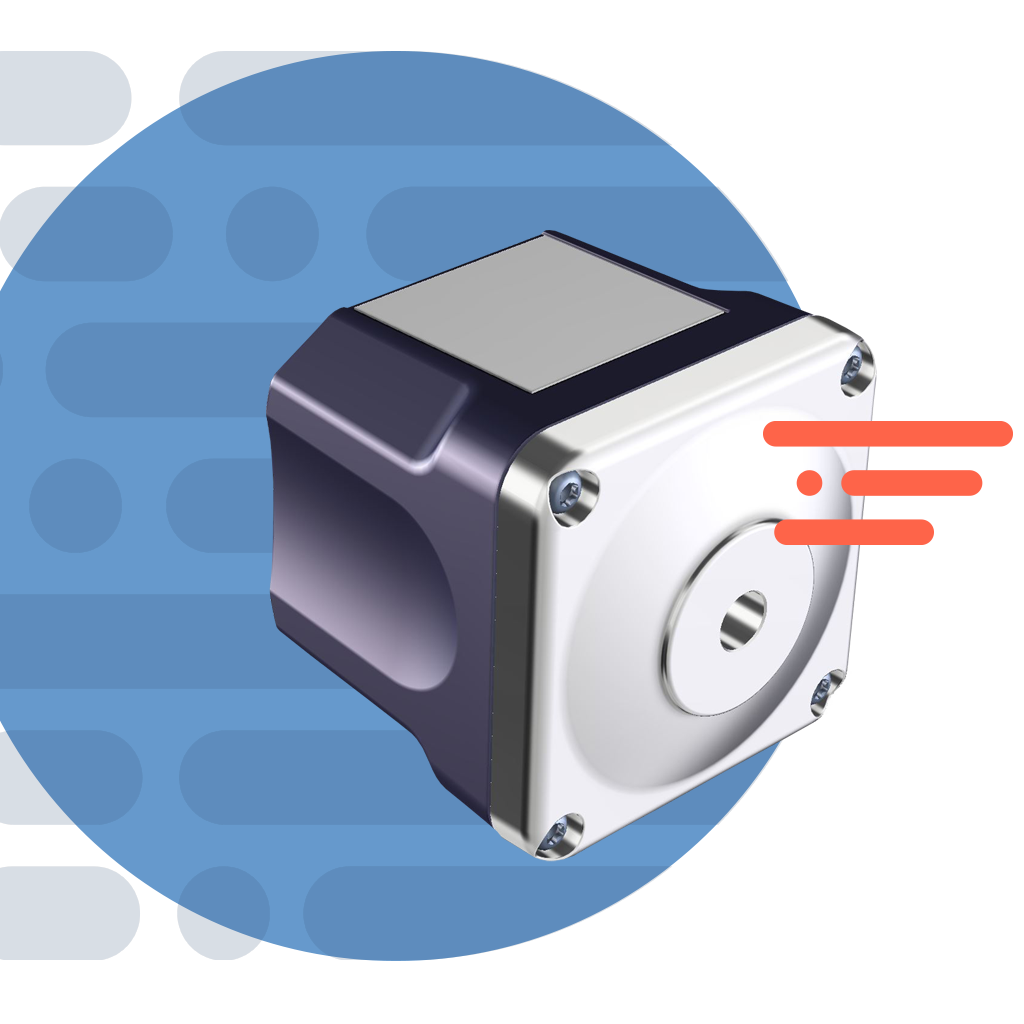

uBlock

Functional Specification – uBlock IIOT Wireless 3 axis Vibration & Temperature sensor

Finally, a battery powered vibration sensor that has been tested for long range in an industrial environment, detects shaft, bearing and gear faults, doesn’t compromise on frequency resolution and has a battery that will last five years!

- Fmax 6.3kHz for all axes

- 15bits scaled between 2g-16g

- Completely programmable trigger parameters

- MEMS Accelerometer

- Frequency accuracy within 0.2%

- Device can sample at several rates with either 18k or 32k samples

- Embedded filtering and OA Parameter engine

- 1200mAh Lithium Thionyl Chloride 3.6V battery

- 5 years of battery life on daily logging

- 6 years of battery life 2 x per day OA mesh

- IP68 rated enclosure

- (4.4 x 4.4 x 4.7cm) antenna reaches 120mm

- Sensor mounting thread M6

- Weight 160 grams

Key Features

Small – only 4.4 x 4.4 x 4.7 cm; with an IP68 rating

Handheld, Cloud Gateway and automation-friendly solutions

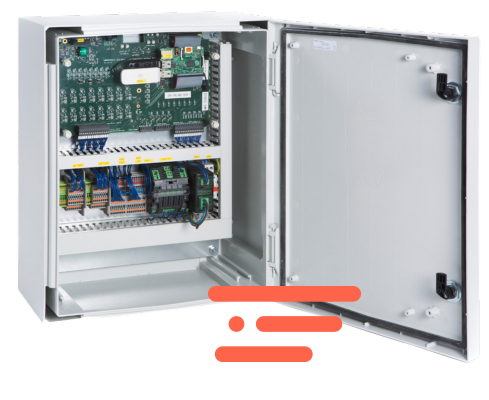

uBridge

uBridge 16842 Intelligent Online Device

The uBridge16842 is a truly IIOT/ Industry 4.0 compatible Intelligent Condition Monitoring solution for all balance of plant and critical-spared assets.

Huge reduction in sampling timescales when measuring low frequency data elements, plus optimisation of the whole 24 bits across the 2Hz-2kHz frequency range through the lower sample rate and associated 2kHz Anti-Aliasing Filters.

Local Intelligence and Storage/ Long-time samples – the use of a single board computer allows the allocation of up to 0.5GBytes of RAM to the sampling engine, hence the actual measurement limit (assuming a 32byte float) is around 100Million samples (for a single channel).

PLC Interface (with no additional hardware) – far too often vibration data are stored as time and frequency domain primitives with no derived intelligence and only basic symptoms. The locally driven uBridge intelligence will allow any system integrator to add their own intelligence.

Key Features

16 channels in two sets of (8 x 24bit) channels @ 51.2kHz sample rate simultaneously

Allocated 0.5GB RAM enables super-long sample sets (> 40 minutes @ 51.2kHz sample rate)

PLC Interface of six intelligent outputs to relay ‘expert derived condition state’

Truly IIoT and Industry 4.0 compatible

Development

Bespoke and white-label solutions start here

We’ve developed bespoke vibration measuring devices for a number of companies over the years. Let us know what you need and we’ll respond to your overview specification, taking into account our schedule, available electronics and firmware building blocks.

Our hardware is also available for badge labelling and integration into your PdM solution portfolio. We’re experts in accelerated integration and have code snips/APIs and apps for integration.

Key technology elements

01

24 Bit Data Converters

- Quality Piezo sensors

- Local Interface to PLCs

- Constantly scanning wired online system

- All data stored locally as well as to Cloud

02

Multi-Platform Codebase

- Web-based Application

- CMMS & OPC interfaces

- 4-20mA inputs and outputs

- Lubrication Management

- Vibration Monitoring

03

Long Range IIoT (up to 200m)

- BLE for near field comms

- High-speed wireless

- Battery-powered IIoT sensor lasts five years

04

Intelligent Self-Learning Analysis

- Customisable dashboards

- Email alert notifications

- Statistical, threshold and learned alarms

- Instant Status Summary/Visuals

- Remote analysis and support 24/7

We at IMV (Japan) have used Diagsol several times over the last 5 years to develop bespoke PdM hardware and software and our end users/customers are all very satisfied with the engineering quality of the DSL PdM building blocks, we will most certainly use them again.

Toshi (Kazu) Igarashi | Executive Manager | Overseas Division

Diagsol are our chosen Predictive Maintenance Providers for all of our UK manufacturing facilities as we believe they are very easy to work with and professional at all times and they actually care about optimising our PdM implementation.

Alan Watt | Group Engineering Senior Manager | Britvic Soft Drinks