Vibration

Solutions

Moving beyond state-of-the-art products, our expertise extends from web-based software for reliability and condition monitoring to full remote support around the clock.

Discover how we can help you avoid unnecessary, unplanned downtime with our holistic approach to end-to-end reliability. Get ready for Industry 4.0!

Remote Analysis Services

Our dedicated team of Reliability and Vibration experts as and when you need them

Our Predictive Maintenance specialists are highly trained and our advanced analysis software tools are only available to our in-house team. Our remote Analysis services ensures your assets are monitored by a team of dedicated professionals 24/7 in the language of your choice.

All email alerts are reviewed/ investigated and, where appropriate, a maintenance advisory provided within 24 hours.

Key Features

Advanced analysis

In-house experts

24/7 support

Quick turnaround

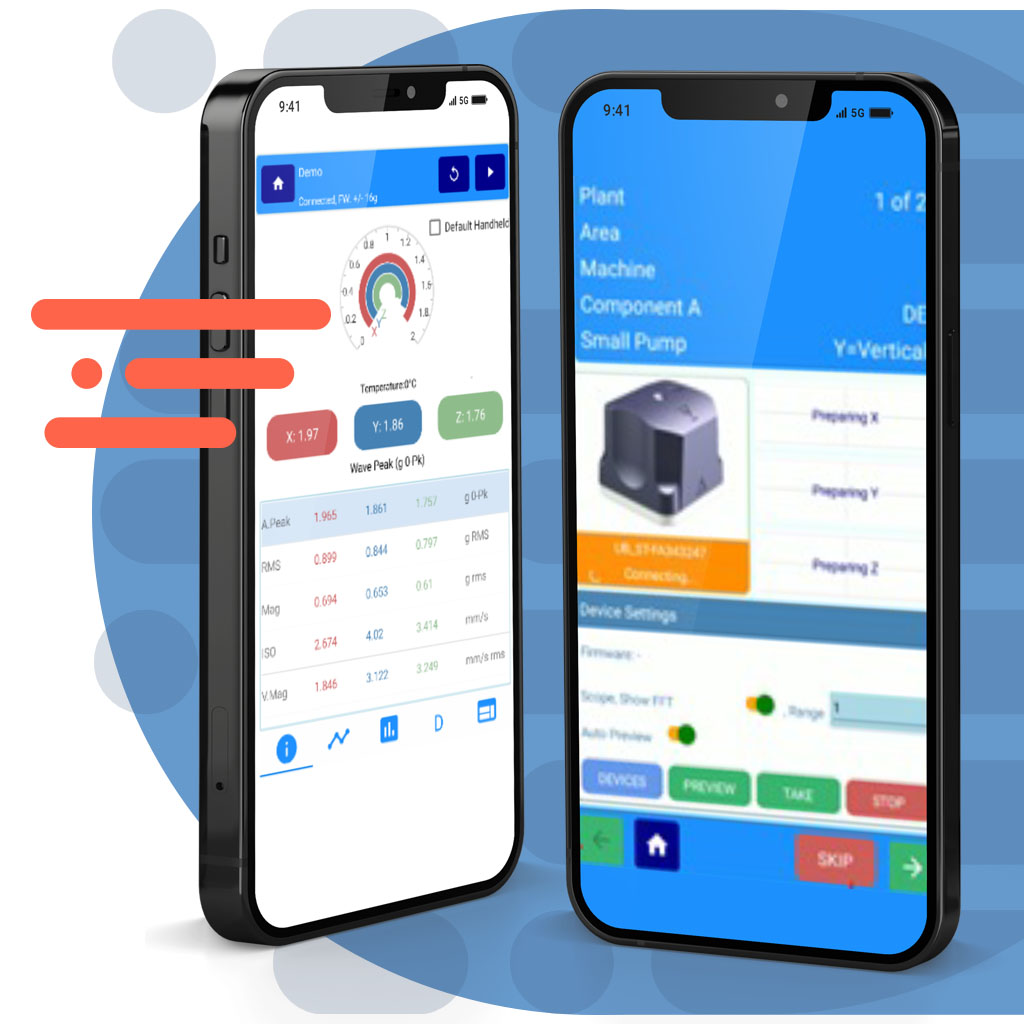

Handheld Solutions

uMobile & Vibra Handheld Android Apps

The uMobile Android application allows an authorised user access to ALL of the due or ‘ad hoc’ vibration, inspection, lubrication or thermal inspections (CAT S61 phone enabled) configured within the UpTime database. Data are unloaded via WiFi or cellular connections as they are taken. In addition to the uMobile solution, DIAGSOL has a vibration-based solution utilising the uBlock (Vibra Mobile).

When combined with the uClip Vibration collector, the uMobile solution provides a world-class condition assessment tool for a fraction of the typical cost.

Key Features

Route-based inspections

World-class tool

Cost-effective

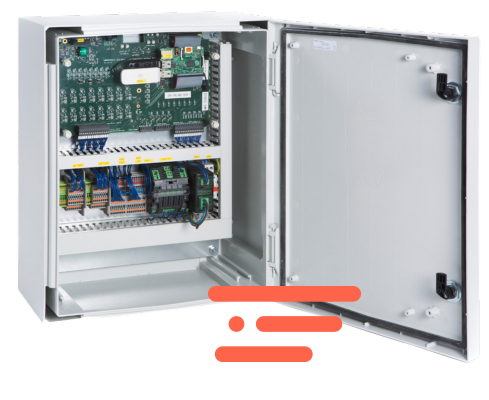

Integration & Machine Learning

A complete vibration data collection solution with embedded interoperability and decentralised decision making to optimise reliability

Our flagship uBridge hardware platform is a smart condition-monitoring system designed from the ground up to push cloud and local intelligence into any 4-20mA-compatible system.

Key process/speed and manufacturing data can be combined with an array of reliability metrics to leverage machine intelligence into reliability. UpTimeWorks uses data clustering and learned diagnostic symptom tags to build up accurate machinery component cases with proven alarm setpoints.

Key Features

Technically superior to most online systems

IIoT and Industry 4.0 compatible, programmable and scalable

Transfers vibration data to a cloud-based decision-support database

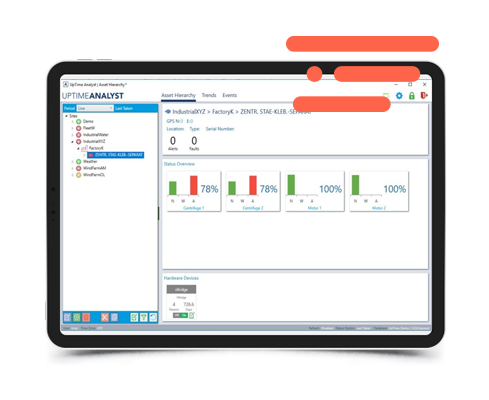

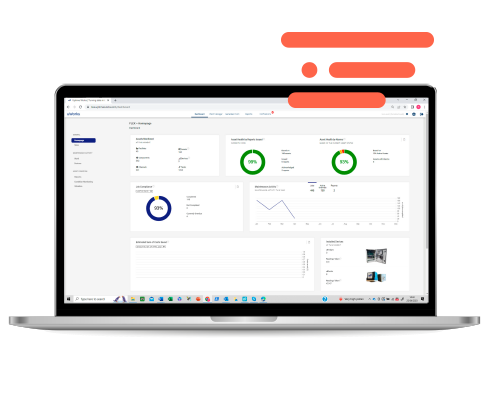

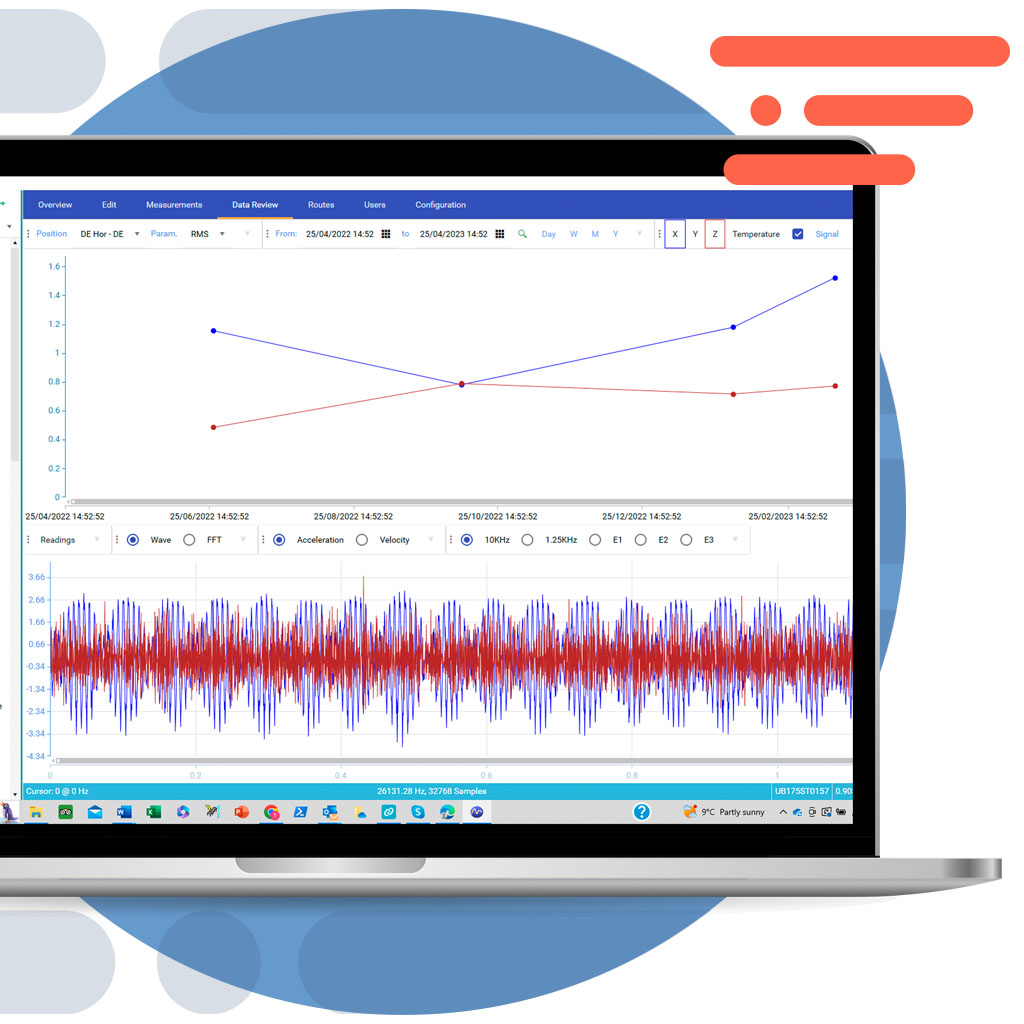

UpTimeWorks

Where reliability and predictive technology exceed expectations

uWorks’ innovative, scalable reliability platform, bringing you innovation through new technologies. The UpTimeWorks platform’s multi disciplinary approach to condition monitoring makes the most of wired IoT sensors and web-based software to plan, monitor and action your complete reliability program. Thanks to its centralised database, it brings together multiple assets measurements for early fault detection.

UpTimeWorks key technology elements

01

High-End Vibration Data Collection

- Hardware for your unique vibration data collection requirements

- Tailored to your systems’ criticality,

- Accommodates multi-channel/route-based devices

- Leading-edge scalable IoT products

- Full integration with our software

- 24-bit data collection capabilities for early-stage defect detection.

02

Online & on-prem Software

- Centralised database

- Digital work-order management

- Reliability program on component level

- High traceability

- Integrated oil laboratories

- Generate (lubrication) reports

- Interactive dashboard

- Multi-language

03

Advanced Vibration Analysis

- Advanced data visualizations

- Threshold functionalities protect your assets

- FFT/waveform analysis

04

Mobile Apps for Route-Based Inspections

- Visual inspections

- Lubrication

- Oil samples

- Vibration measurements

- Thermal-graphic images

Vibra Mobile

Route-based readings from our devices

Vibra Mobile runs on Android for route and off-tour walk-up collection of data from uBlock devices. Data are passed up to the Vibra Cloud Database via 4G or Wi-Fi and analysed within the Vibra Desktop Application.

Vibra Desktop

Data configuration, analysis and route management suite

The Vibra desktop app supports a number of functions and can also be run on the Vibra Gateway:

- Database build/alarms

- Data analysis

- Route creation

- Alarm review

Vibra Gateway

Embedded automation solution

This Linux-based App/Image allows data collection from devices such as the uBlock and uBridge within an enterprise Firewall (LAN). Data are all stored locally and can be exported to the plant Automation system via OPC; Status and Action tables are available for plant HMIs. Your DIAGSOL remote analyst can VPN into the analysis suite to advise on any critical issues.

Key Features

Embedded

Inside firewall

Cost-effective

We at IMV (Japan) have used Diagsol several times over the last 5 years to develop bespoke PdM hardware and software and our end users/customers are all very satisfied with the engineering quality of the DSL PdM building blocks, we will most certainly use them again.

Toshi (Kazu) Igarashi | Executive Manager | Overseas Division

Diagsol are our chosen Predictive Maintenance Providers for all of our UK manufacturing facilities as we believe they are very easy to work with and professional at all times and they actually care about optimising our PdM implementation.

Alan Watt | Group Engineering Senior Manager | Britvic Soft Drinks